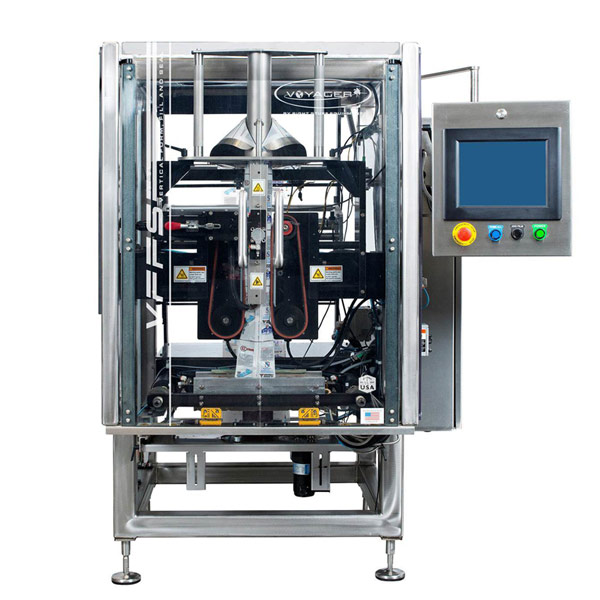

24 Jul Typical Features to Consider when Buying a Vertical Form Fill and Seal Bagging Machine (VFFS)

When buying a VFFS bagging machine there are many important features to consider. Right Stuff Equipment as a VFFS manufacturer has outlined those important considerations below.

Controls

The PLC in the VFFS bagger controls the functionality and the operations within the machine. Allan Bradley is the most widely supported PLC in the industry. It is also the most robust and popular in most manufacturing applications in the USA. Less expensive PLC and HMI sets may have less capability, less memory, slower processing speeds and smaller screens HMI’s come in monochrome or color and in different sizes. The size of the screen allows the programmer to put more buttons on each page the operator interfaces with. This make navigating the pages much easier. Adding color calls attention to the operator. Examples include using Red, Yellow and Green status buttons to tell the operator the condition of an operating parameter.

Frame Construction

VFFS Frames come in various forms. The heavier the frame construction; Typically, from 2.0” to 3” box tube, the smoother the performance. Bolted frames mean more possible places for micro or bacteria to grow. They also present an opportunity to loosen over time. A welded frame is more sanitary and will provide a lifetime of stability. A stainless frame wont chip, rust or give your 3rd party auditors reason to deduct points. Other frames use less expensive carbon steel and the finish is epoxy painted or powder coated. These eventually chip and get surface rust. The epoxy finish is easier to touch up when this happens.

Remote Communication Port Via Ethernet/IP

This feature allows the manufacture technician to remotely monitor and adjust settings on the vFFS machine via Ethernet for maintenance and troubleshooting. It assists the customer with a fast, remote response for diagnosing operating problems

Film Tracking

Laminated and converted film webs often go through multiple steps in the of creating the final wound roll of film. When film gets slit, printed, laminated etc. it means it can be unwound and rewound for each step. This often creates uneven tension within the film roll. The result is that film will tend to drift left or right as it travels through the bagger. It then needs to be tracked on the bagger with a tracking system so it runs through the center line of the bagger. This allows the edges line up and make a proper fin seal. Film tracking is either done manually or automatically.

Automatic Film Tracking (AFT), means when the tension changes within the roll of film and the film wants to walk left or right, the AFT will automatically move the film carriage left or right to keep the film centered and the fin seal intact. This is accomplished by using a sensor that monitors the position of the film edge as it travels through the bagger. The entire film carriage moves which also includes the printer if it is installed. The printed image always stays in the right place. If AFT is not on the machine, then manual adjustments must be done when the film walks one direction or the other. This is done with an adjustment wheel that moves the film carriage. Losing the fin seal is a very common problem when the film tension is uneven, and the adjustment is manual. The operator often cannot react quickly enough to make the change needed to track the film properly.

AFT reduces lost film (which typically costs 5-15 cents per impression), down time, and yield loss.

Film Unwind

Film also needs to be indexed for each bag to be filled and cut. The low-cost way to unwind the film is to the pull the film through the VFFS bagger. That can result in a couple of problems: One, the film stretches as it is pulled resulting in the position for cutting and sealing not being precise. Two, the film slips as belts try to pull the film through the process. The resistance of the film to pulling is high as it the film travels over several rollers. The pull-down belts can slip as a result. These machines typically have a film brake on the unwind section of film as a way to keep even tension on the film.

The upgraded option is to have a powered unwind of the film roll. The film is released as it’s needed to make bags. A dancer roller senses film tension and sends a signal to the powered unwind motor to release film. This keeps the film lightly tensioned through the machine and helps prevent stretching and belt slipping. Higher end machines running high speed, big bags, or zippered film usually offer power unwind.

Jaw Closure Set

Jaw are normally closed through a mechanism controlled either pneumatically, stepper or servo motors. Pneumatics use air cylinders which eventually leak and need to be replaced. The variability of plant air pressure can also cause pressure drops and performance problems when pneumatics are used. They are also slower and less precise than stepper or servo motors. The result can be inconsistent end seals.

When using steppers or servos, the jaw closure can be more precisely controlled in terms of speed, dwell time and pressure. Keeping in mind that the variables that can be controlled on the VFFS machines to insure proper seals are: Pressure, Temperature and Dwell time. The stepper and servo motors improve performance in Pressure and dwell meaning more consistent and more controllable seals. Steppers can run over 100 cycles per minute. Servos are used in very high speed applications and continuous motion machines.

Deflators

Deflators are a sponge type material that gently pushes the air out of the top of the bag when the jaws close. This is done to keep the bags from having too much air in the head space.

Top Plate

The top plate covers the top of the machine. Without the top cover, the film is exposed to the potential of material falling onto the surface as it travels through the rollers and toward the sealing area. It is also piece the filler is mounted to if a volumetric filler is used. In those cases, a heavier gauge metal is used. Scales have their own platforms so the top plate us just used to keep foreign material off the film.

Seal Cooling

Seal cooling is an option to blow air on the seals to help set the sealing of the laminate layer in the film.

This is useful when running at high speed and when a dense product is dropped into the bag. The option helps prevent fracturing of the seal when the product is dropped into the pouch as well as reducing the set time of the sealant layer after heat is applied.

Product Catcher

The product catcher allows product to drop while the jaws are in the process of sealing the previous bag. This reduces the drop time and improves cycle speed. This is important for products that are light density and don’t fall freely. These light products tend to ‘string out’ as they fall into the forming tube. Examples include seasoned popcorn and snack foods.

The product stager allows heavier product to drop while the jaws are in the process of sealing the current bag. The stager also can absorb the energy of high-bulk density products minimizing the drop distance onto the horizontal seals.

Printer/Labeler

A Thermal Transfer printer allows you to put date code, lot code and other product specific information on the bag. The options mentioned above will assure the placement of the information is precise. Many brands have a specific window printed on the film where they want that information to be printed. If the film stretches, then the placement will move relative to the window. To install a printer, a printer bracket is needed. This is a universal bracket that will work on all the popular TT printers.

Some companies prefer a label on the bag. In those cases, there are labelers that can be installed on the bagger with will apply the label to the film at the forming tube station. An alternative is to place the label on the bag after it leaves the machine. Labeling is not as precise as TT printing, but common when non-Pre-printed film is used.

Load Shelf

The load shelf comes underneath the bag like a shelf to support it while its being filled. This is important when filling heavier weights in a VFFS bag. More than 1.5-2 pounds. The combination of seal cooling and the Load Shelf keeps the bottom seal from rupture while the laminate layer is finalizing the curing process. The Load Shelf then ejects the bag onto a discharge conveyor.

Bag Dimensions

The bag dimensions are measured by min and max width of the bag and min and max length of the bag the VFFS bagger can produce. Typical standard widths range from 8 to 16 inches. A wider capability offers more flexibility to run a variety of larger bags in the future. A wider bag also allows the product to fall into the larger opening faster and allows faster cycle speeds.

The bag length is determined by how long the film can be pulled and sealed on the fin seal. Typical lengths range from 10-18 inches. Many machines can do a ‘double pull’ to allow a longer bag to be made.

VFFS Bag Styles

- Gusset –Making a gusseted bag, helps utilize the space of the bag more fully and helps the bag stand up on the shelf for merchandizing purposes. It is made by tucking the film in at the bottom or top and bottom

- Flat Bottom-This is a similar bag shape as the gusseted bag but tucks the bottom in a horizontal orientation. This further helps with the bag’s ability to stand up on a shelf and merchandize well.

- Doy Style –Doy Style bags are also referred to as Stand Up Pouches (SUP). To make a Doy style bag on a VFFS machine, special tooling is needed in the former and the jaws as well as some additional capabilities built into the bagger.

Forming Tubes

You need different forming tubes for different width bags. The wider the bag, the larger the tube needed for the film to wrap around it. Bags widths are measured in lay flat, which means you place the bag flat on the table and measure the end seal width. If running bags with a zipper or one-way vale inserted in the film, then former needs to be made to accommodate the zipper or valve. Formers have shoulders the film travels over as the film transitions into a tube. Sticky films may require a dimpled shoulder surface to reduce friction.

Static Elimination

Static electricity is created as some powders move inside the hoppers. Static charge can also be created as the film unwinds and passes over rollers. Some products like powders, float or cling when static electricity is present. It can cling to the inside of the bag as it is being formed, and get in the seal area as the jaws close. This can cause poor seal integrity and a bad appearance. Deionizers are available to reduce the charge in the film and powder reducing the problem. Anti-static film and be used and the anti-static material in the discharge cone is also an option when using a rotary scale to reduce the charge in the product.

Bag Stripper

When filling light weight products such as tea and spices or small bags, the bags may tend to stick to the horizontal jaws after sealing. Seals will be compromised if there are bags stuck to the jaws. Bag strippers use compressed air to gently blow the bags off the jaws

One-way Valves

One way valves are used to control the gassing of product within the bag. Usually coffee. As the product creates gas, the one-way valve allows the gas to be released without allowing ambient air back into the bag. This helps reduce oxidation of the coffee. There are two basic styles of valves.

Hole Punch

A hang hole is often needed to merchandize the product. Holes can be mechanically or heat punched. Round or sombrero cuts are available. When hole punches are used, the top seal needs to be larger to seal enough film above and below the hole. s

Tear Notch

Tear notches are small notches removed from end seal of the bag and make opening the bag easier. The can be placed at the side or top.

Jaw Seal and Cut Orientation

Seal patterns normally have a corrugated pattern to insure good seal integrity. They can be vertical where the corrugates pattern is in the same direction as the length of the bag. A horizontal pattern is when the corrugates direction runs perpendicular to the bag length. A 45 degree angles are sometimes used as well.

Horizontal seals typically give better seal integrity.

The corrugated pattern can have different pitch (# of corrugates per inch) and different shapes. Let the machine maker help determine the best options for you.

he bag end can be serrated or smooth end cut. The serration can also have different pitch or number of points per inch. The serration can act as a natural tear notch for opening the bag from the end.

Vacuum belts

These are used to create a vacuum between the belt and the film, creating a vacuum grip on the film. It helps reduce the wear on the belts by reducing the pressure needed to pull the film.

Nitrogen dosing

Nitrogen (N) helps extend the shelf life of products that degrade in the presence of Oxygen. Examples are nuts, granola and chips. Oxygen levels in the 2-5% range can normally be achieved by introducing nitrogen into the forming tube as the product is dropping into the formed bag. The N is delivered by a gas or compressed liquid N tank or N generator.

Bulk Flow Metal Detection

Metal Detection is not possible with a conventional packaged metal detector if the packaging material is metalized film or foil. In those cases, bulk flow metal detectors can be mounted under the filler to inspect product as it flows into the bagger. If metal is found, the metal detector can divert the material or send a signal to the bagger to stop so the bad bag can be removed.

VFFS Specialty Machines

- Quad seal bags- This is a specialty bag used largely in the coffee industry. It has sealed edges on all four sides of the bag and square flat bottom. This is considered a specialty application and requires special tooling and baggers set.

- Wash down version- Typical machines are rated IP 30 standard and come with control panels with the same or similar rating. Wash down machines will be required in certain environments such as dairy, USDA and IP ratings like IP 66, 67 or 69 might be required.

- Bag in Bag- This is a very specific application with one machine stacked on top of other to make small bags that then go into a master bag.

- Continuous Bagger- The clear majority of the baggers produced are intermittent in their operation. Continuous machines do not start and stop the film but run it continuously at up to 200 bpm. Many products don’t have the right properties to fall fast enough in discreet batches to fall into a bag at that speed.

- Big Bag- Used a lot in pet food applications.

- Stick Pack- Stick packs are specialty machines to make the stick that have become popular in drink mix and sweetener applications. They can come in single lane or multi lanes. Multi lanes allow for much higher production in bags per minute.

- Sachet- Either 3 sided of 4 sided machines. Often used for sugar packets or retail tea flow through bags.

- Squeegee Seals- Specialty Application for running liquids with no head space in the bag

- Rotating Jaws- Specialty application primarily employed to make a doy style bag on a VFFS. The result is the bag gets filled from the side and the doy is formed in the front.

Ancillary Equipment to a VFFS Application

VFFS Bagger machines will need additional equipment upstream and downstream. Some typical additions include:

- Equipment platform- Needed if there is a rotary Scale.

- Filler-Usually an auger, scale or cup filler mounted above the bagger to provide the proper amount of product into each bag. Different products have properties that will determine the best filler option.

- Feeder to the Filler- Bucket elevators, Pneumatic, screw and puck feeders are typically used to convey product from the floor level up to the Filler. Different products properties will determine the best way to convey material. Sometimes there will be a floor above the bagger where a hopper is filled directly above which then feeds the filler.

- Take away Conveyor- Conveyor transfers the newly made bag away from the bagger.

- Packaged X-Ray, Metal Detection and Check Weigh- Inspects for proper weight and contaminants in the bag after it has been formed and filled.

- Accumulation Table- Often, a rotary table catches the product from the takeaway conveyor so the next step of casing can be accomplished easily.

- Case Erection and Sealing- Case erection and sealing takes place manually or automatically after the product has landed on the accumulation table.

- Case Coding and Labeling- Case coding and be done with a printer or a labeler. There are many styles and each has its’ pros and cons.

If you have any questions or comments please email us info@rightstuffequipment.com or call 303-327-4704. Thank you.