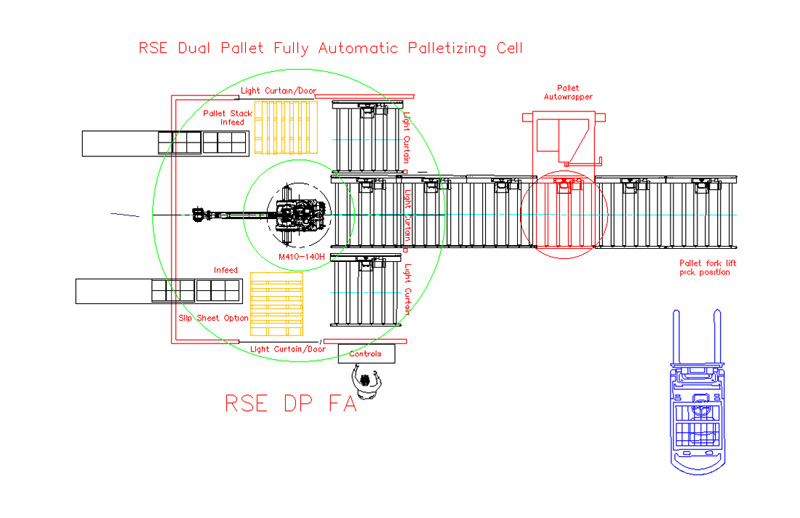

Dual Palletizing – Fully-Automatic

The Dual Pallet Fully Automatic Palletizing Cell is designed for the mid-sized and large companies with multiple packaging lines and need a palletizing station that can handle two production lines simultaneously. It can run up to 14 cycles or picks per minute. The number of packages to be picked per cycle will be product dependent. The two lines feed packages to be picked via independent conveyors which are picked and placed on two correlating pallets. Recipes programmed into the robot control the pallet patterns. The Fanuc Multi Axis Robot Arm has capacity of 140 kg (308#) is the capacity of a maximum weight per pick including the End Of Arm Tool (EOAT). Higher capacity robots are available for heavier items but the 140 KG capacity handles most applications. The system can run various packages such as cases, large bags, pails and others which will be placed on the shipping pallet. A fork lift operator loads the pallet into the two loading stations. If a bottom slip sheet is required, the operator will place the sheet before loading in the pallet station or an auto slip sheet option is available.

The pallet will be placed on a pallet conveyor which transfers it into the cell through a light curtain set that acts as a safety system. Light curtains and interlocks on doors prevent a person from entering the cell while the robot is operational. The cell includes two package infeed conveyors designed to index the packages to the precise pick positions without back pressure. Once a package is in position, a sensor will communicate to the robot that the package is ready to be picked. An indicator light will indicate an operational status to the operator from a distance.

The HMI has a color 10” screen which is intuitive and easy to follow, with three levels of access for the operator, maintenance, and engineer levels. The HMI will provide details on each fault and steps to clear them. The HMI also contains a manual, schematics to facilitate maintenance and engineering when needed. The Allen-Bradley PLC controls the entire system while the HMI provides an intuitive set of screens to run the palletizing cell. The EOAT is specific to the type of package to be loaded.

Option Packages include:

- Specific EOAT Required

- Case Labeling

- Case Direct Printing

- Automatic Slip Sheet Placement

- Heavy Duty Robot with 180kg Capacity

- Automatic Pallet Dispenser

- Automatic Stretch Wrapper

- Automatic Pallet Labeling

Considering your options for robotic palletizing? Contact Right Stuff Equipment at 303.327.4704, or Email Us for more information about robotic palletizing.